27 Oct Commissioning of the Resmacc pilot for the solvolytic recycling of carbon fibres reinforced plastics

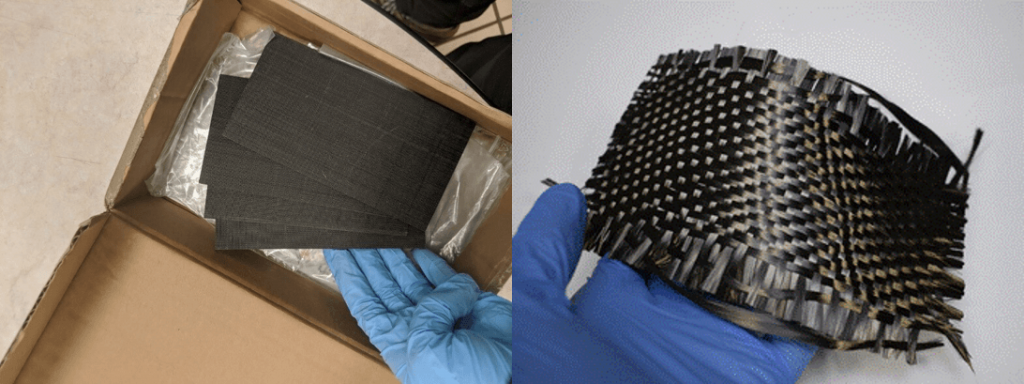

Carbon fibres reinforced plastics (so called CFRPs) are advanced materials constituted of a carbon fibre-based reinforcement and an organic polymer binder. They are the solution of choice for every application where a combination of lightweight construction and high mechanical resistance is required. They are thus found in fields as diverse as aircraft construction, wind power production and car making. The carbon fibres they contain have both a high value and a high energy footprint. Therefore, it is a shame not to recycle CFRP production scrap and CFRP containing end of life products.

The current reference solution for the recycling of CFRPs is pyrolysis. Unfortunately, this technology features a few drawbacks such as its CO2-footprint and its negative impact on the mechanical properties of the recycled carbon fibres. This is the reason why, Extracthive has been developing, since 2016, an alternative recycling approach based on solvolysis. In this approach a unique combination of solvent and catalyst allows for the depolymerisation of the resin at moderate temperature and pressure thereby releasing clean and undamaged fibres.

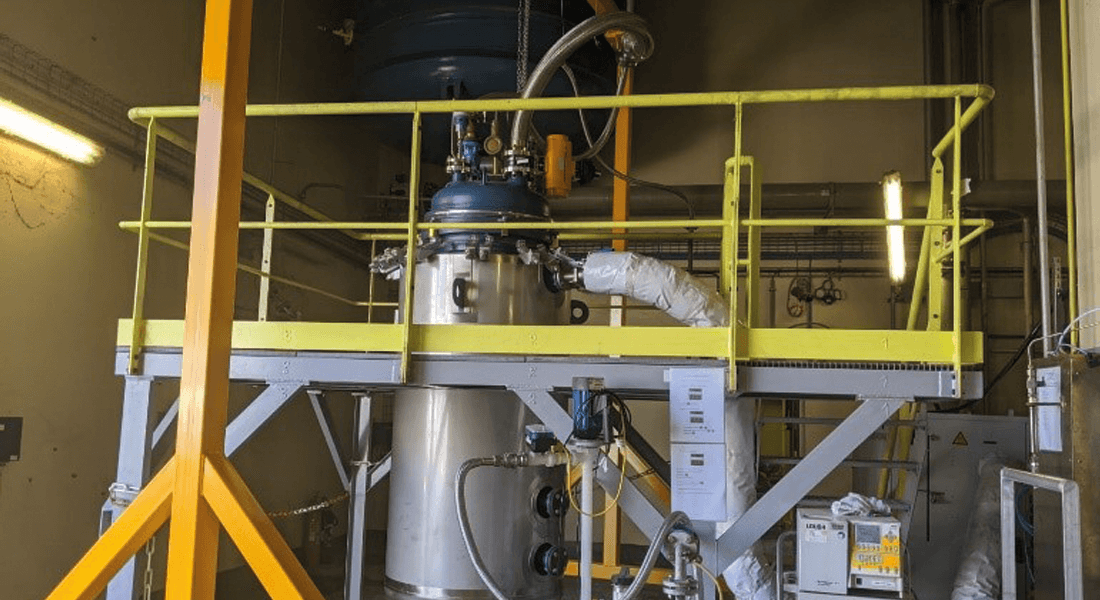

The first successful scale-up was supported by both CEA and IMN. We managed to operate on a regular base in a 10 l hastelloy autoclave reactor enabling to investigate in detail the versatility of our approach. Furthermore, Extracthive recently commissioned a 800 l pilot scale-reactor design in collaboration with the company De Dietrich. Thanks to this toll we are now able to produce larger quantities of recycled carbon fibres (up to 30 kg per batch) for assessment by future customers but also to test possible post-treatment solutions. In addition, the size of the reactor is suited to test our process on full scale piece of CFRPs based pieces of equipment like aircraft turbine blades or hydrogen tanks.

Our next goal is to design and commission a 4 m3 demonstration reactor with a production capacity of 1,5 t/d. This plant will include a fully integrated solvent recycling unit in order to further reduce the environmental impact of our process. For this purpose, we received the support of the EIT RawMaterials in the framework of the Relicario project to which, among others, CEA is contributing.

Further information at: https://www.phyre-recycling.com/

The Resmacc project is funded by the Région Occitanie and the European Union in the framework of the ERDF call Readynov.

This project has been carried out within the Metnet network. This network consists of several pilot plants in Europe, covering many different aspects of mineral processing, metallurgy and production of metals. Through Metnet the customers have access to a network of knowledge that can work cross-sectorial and innovatively by combining the expertise of all members. You can find more about the METNET network here.