Advancing Collaborative Solutions: Highlights from the METNET Meeting

METNET, a collaborative network of European research institutes specia...

29 May, 2024

Metnet is a network of independent European pilot plants that design, construct and operate large pilot-scale equipment for mineral and metallurgical processes. The network is coordinated by Christa Nimbona, R&D Engineer at Elkem ASA.

Its key market is the mining, mineral, metals and recycling industries. Customers are also found among technology and equipment providers as well as related industry.

Metnet offers a complete solution in the value chain from raw material preparation to casting through a single-point of contact. When contact is established, the business arrangements are set up between customer and Metnet partner. This guarantees the confidentiality of the customer´s research.

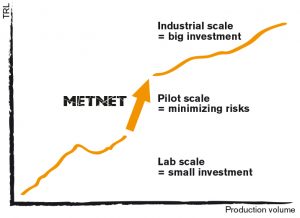

Pilot plants facilities are the key in the innovation process to bring new technology into practice and thereby creating benefit for the industry.

By bringing processes and techniques from a low TRL to high TRL, pilot-plant trials are of great importance to minimize technical and financial risks. Consequently, access to pilot plants is necessary to bring ideas or concepts into industrial use, i.e. “Crossing the valley of death”.

Discover METNET offer

METNET, a collaborative network of European research institutes specia...

29 May, 2024PROMETIA’s Scientific Seminar, held in Lisbon, Portugal, from 28...

19 December, 2023Join Us for the 10th Scientific Seminar & Register now! Dates: Nov...

18 September, 2023In pyrometallurgical process management, prompt responsiveness is key,...

12 July, 2021The Metnet network consists of several pilot plants in Europe, covering many different aspects of mineral processing, metallurgy and production of metals. Through Metnet the customers have access to a network of knowledge that can work cross-sectorial and innovatively by combining the expertise of all members. By contacting either of us, you will find the specific competence and equipment you need.

We would like to thank our Industrial Support Organisations for supporting the development of our network and helping us identify the needs of industry.

Metnet Industrial Support Organisations (ISO)