08 Jul CRM Group Agglomeration Platform

In the context of resource scarcity and stringent environmental regulations, CRM Group has continually invested in new technologies and skills dealing with agglomeration of fine (secondary) raw materials and metallic turnings/swarfs, ending up in a unique and versatile pre-processing platform.

Thanks to this wide range of cold processing equipment, CRM Group is able to test and compare various technologies in an unbiased way and on a large panel of (secondary) raw materials to maximise their value in use a.o. in the foundries area.

The latest acquisition is a de-airing extruder equipped with a vacuum pump in order to improve cohesion of particles in the extrudates, thereby reducing the consumption of binders compared with other technologies. It can handle a flow rate of up to 100 l/h with a pressure of 25 to 50 bars. This equipment is designed to perfectly reproduce results obtained with industrial extruders.

Strongly related to this specific expertise, CRM Group actively participates in the European CarSiFer project coordinated by Revatech (BE- Suez Group) and co-funded by EIT Raw Materials. Within this project Revatech aims to recycle in foundries unused & currently dumped industrial waste still containing valuable metallic elements, with two major targeted impacts: landfilling avoidance and accessibility to sustainable alternative raw materials.

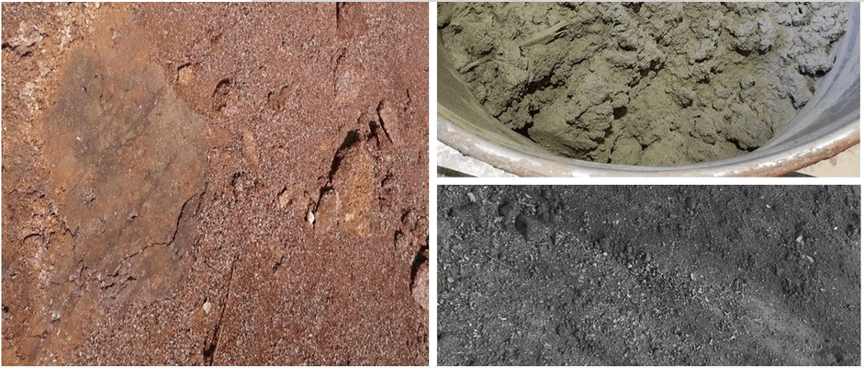

As a first step, waste streams are being identified and analysed to determine their true potential. These streams are then collected and assembled in such a way to meet the compositional requirements of foundries, but also to increase their mechanical performance after agglomeration, thereby improving their recyclability. These streams are finally agglomerated to produce briquettes in order to validate the entire waste recycling process on the basis of tests at industrial scale.

The expertise and equipment of CRM Group in cold agglomeration enables to meet the major challenges that are at the heart of this project: depending on its origin and history, the waste may occur in very different forms, like fine powder, slightly oily grinding sludge, filings or pasty sludge… A wide panel of equipment is thus needed to adapt the agglomeration path to the variety of waste streams to be recovered.

By the end of the year, large scale tests will be carried out in partnership with Revatech in two foundries on two different “waste” streams, prepared following customised agglomeration procedures currently being optimised.

This project has been carried out within the Metnet network. This network consists of several pilot plants in Europe, covering many different aspects of mineral processing, metallurgy and production of metals. Through Metnet the customers have access to a network of knowledge that can work cross-sectorial and innovatively by combining the expertise of all members. You can find more about the METNET network here.