21 Feb Successful test on the new Casting Simulator

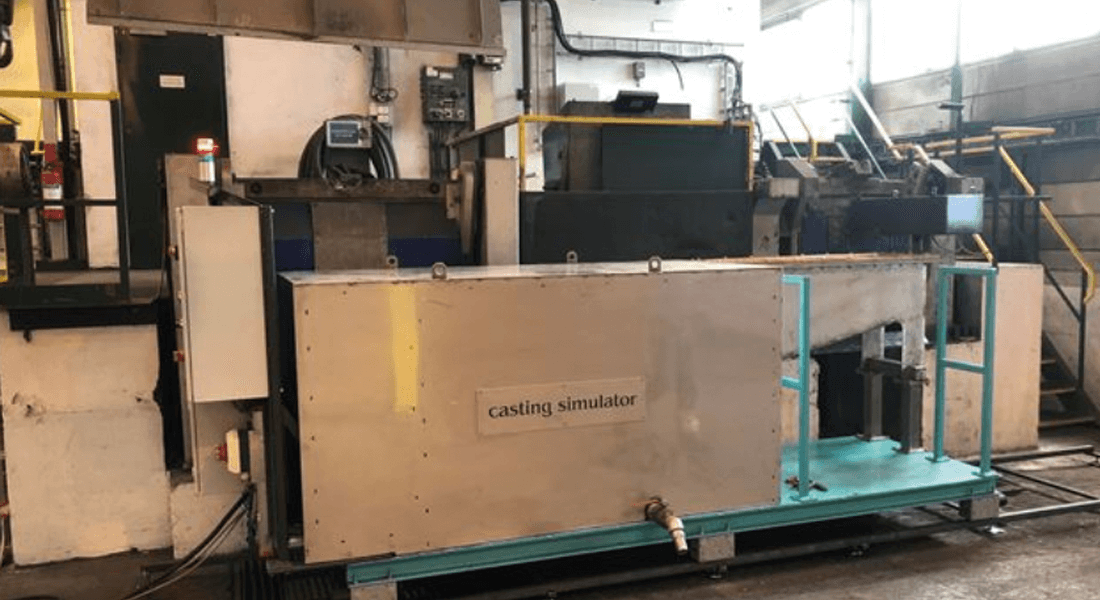

The scope of the project run by Elkem Technology’s Pilot department was to build equipment for casting and solidification of silicon and ferrosilicon alloys on a laboratory scale.

A 250kW induction furnace is used to produce the alloy, and the melt is casted via a graphite runner onto a water-cooled Copper plate. The casting simulator produces casting thicknesses between 1 – 8 cm.

In future projects the Casting Simulator will be used to:

- Study the effect of thermal history on microstructures and material properties

- Support the development of new casting technologies.

With the right process design the casting simulator could be used on a broad range of materials. Projects executed at our Pilot department’s facilities draw on resources from several departments in Elkem Technology; Process development, Instrumentation and Electro, Design, Mechanical and Machine workshops manned by skilled and experienced personnel.

Contact person

Siv Håtveit Wik

Department Manager Pilot

Mobile: +47 90574909

siv.wik@elkem.no

This project has been carried out within the Metnet network. This network consists of several pilot plants in Europe, covering many different aspects of mineral processing, metallurgy and production of metals. Through Metnet the customers have access to a network of knowledge that can work cross-sectorial and innovatively by combining the expertise of all members. You can find more about the METNET network here.