Since the mid-2000s, many European Countries, including the EU, have realised how dependent they have become on foreign imports to access non-energetic raw materials. This dependence has been interpreted as a threat to Europe’s industry and global competitiveness. A list of “Critical Raw Materials” was established in 2010 and revised in 2014, 2017 and 2020.

Context

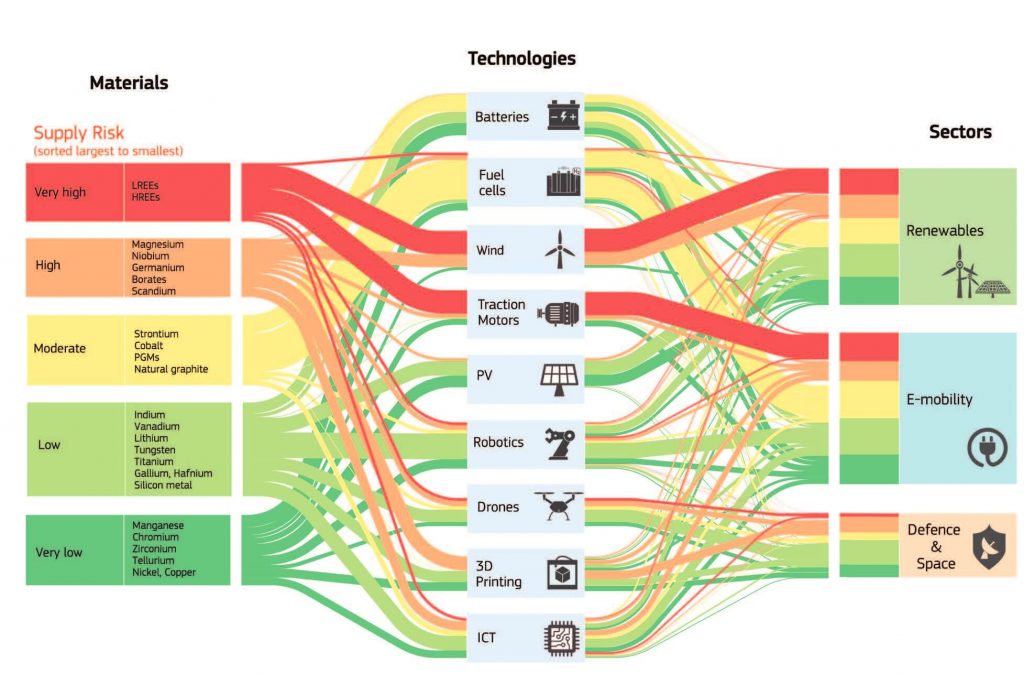

To estimate future demand and competition, raw materials, technologies and sectors need to be taken into consideration together, as several technologies and sectors compete for the same materials. See Figure 1 below:

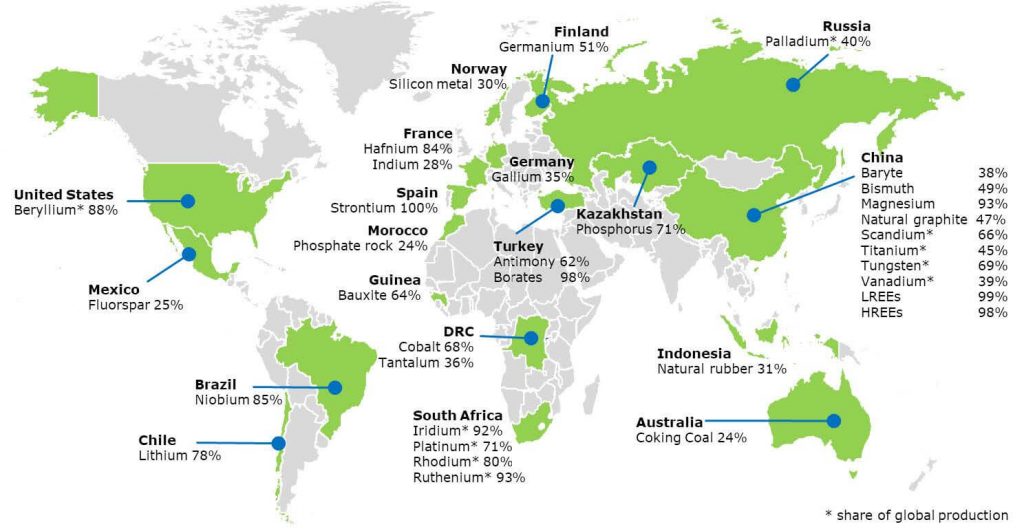

The supply of many critical raw materials identified in the list elaborated by the European Commission is highly concentrated. See Figure 2 below:

Source: European Commission report on the 2020 criticality assessment

- Concerning primary mines, Europe has been mined actively over many centuries and a significant number of the easy-to-access mineral deposits are now greatly depleted. The major opportunities to access raw materials within the EU are in populated areas, in low grade or small complex deposits that may vary in composition over time and contain different sizes of particles from coarse to very fine grains.

The challenge today lays in the evolution of the existing processing of these raw materials to respond to Europe’s constraints.

- The challenges are numerous and the task even more complex for secondary mines. Processes must be adapted and some even specifically designed for the treatment of material or waste. Before their industrial development, these processes must not only be efficient but also consider the economic, environmental and societal aspects in Europe and abroad.

It is therefore necessary for the European industry (i.e. mining and metals industry, technology providers, recyclers…) to access a network of knowledge that can work in a cross-sectorial and innovative way by combining the expertise of all stakeholders.

Flexibility and speed needs to be enhanced and solutions must enter into industrial use faster and more efficiently. Future needs and challenges remain unknown, but the flexibility and versatility of a network and a strong cooperation between research partners and stakeholders will enable industry to overcome these challenges more efficiently.

PROMETIA is the research and integration network designed to address these challenges.