METNET examples

Bioleaching of primary and secondary sulphidic resources

For more than 20 years Brgm has been developing bioleaching of non-conventional resources to recover base and rare metals, with expertise in microbiology, process engineering and process integration. Lab and pilot experiments have been performed on sulphidic materials such as Kupferschiefer resources, rich in organic matter and carbonates. Also, research work led to an industrial operation to recover cobalt from pyritic tailings in Ouganda. Current developments concern 2m3 large batch tests with patented floating mixer and dedicated gas injection to increase leaching outputs and kinetics and reduce CAPEX/OPEX.

New use for roasted by-products

In the production of zinc, a sulphur-rich by-product is formed which is normally disposed of. Reworking the material into a usable product offers economic and environmental gains for industry and society.

Acceleration of industrial innovation to secure high-quality nickel supply

After successful testing of a pilot project by NewEco, a partnership supported by EIT RawMaterials, the ERAMET Sandouville plant in France is undergoing an upgrade that allows it to replace suppliers in the South Pacific with a new European source for nickel concentrate. Read more: https://eitrawmaterials.eu/acceleration-of-industrial-innovation/

From iron and manganese oxide wastes to valuable metal alloys using novel carbon sources materials

The Go-4-0 project aims to turn waste streams from the metal industry into valuable products. The proposed approach relies on synergies between secondary raw materials and reducing agents originating from different sectors (ferroalloys production, ironmaking and end-of-life products recycling). The new processing route will be first optimised at pilot scale at CRM (agglomeration, thermal pre-processing and melting), and then demonstrated in semi-industrial furnaces of Eramet. Read more about Go-4-0: https://prometia.eu/wp-content/uploads/2021/01/11-ERAMET-Milazzo-GO-4-0.pdf

Assessment of a metal recovery plant process modification

When the customer wanted to review process modifications at their metal recovery plant, they contacted the Materials Processing Institute (MPI) for an independent study and plant processing trial. The project resulted in verification of the improved metal recovery process, but also identified additional opportunities for improvement to further efficient and easier management of the operating process.

Development of a Discrete Event Simulation Model for Recycling Process Scenarios

Read about the project where MPI conducted discrete event simulation modelling of two different operating scenarios for recycling and recovery processes using the Rockwell Arena Software.

Elkem Technology is a partner in EMPRESS, EU-project on temperature control

Thermodynamic modelling and reaction kinetics of processes

The Materials Processing Institute (MPI) was asked to develop a thermodynamic and kinetic process model for the compositional evolution of steel, slag and inclusions produced in a secondary steelmaking reaction vessel at operating conditions of 1550-1700 °C. Read more

Innovative technique for the selective recycling of ultra-high performance fiber-reinforced concrete waste

Ultra-high performance fiber-reinforced concrete (UHPFRC) is a new type of concrete with improved performances. It is used in a wide range of applications from the most demanding structures such as bridges to architectural buildings. From the viewpoint of sustainability, the treatment of UHPFRC after the service period of structures should be considered. Read more

Extracting valuable metals from slag

Boliden Harjavalta aims to even better valuable metals recovery from the slags generated in the production of metals. To achieve this the company ordered a pilot-scale project from GTK Mintec. Read more

New construction materials from metallurgical by-products

The RECOVER project aims to convert metallurgical by-products like copper slag and red mud into high value-added construction materials (e.g. thermal insulating building blocks, fire resistant tiles, etc.). Different options for the needed thermal pre-processing of red muds is being evaluated by pilot tests at CRM. Read more

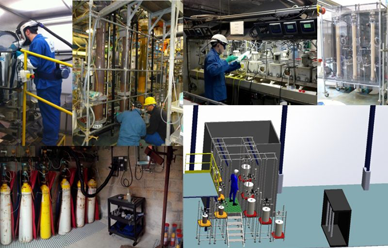

Implementation of a new industrial plant based on pilot scale developments that ables to produce nickel salts and metals

Thanks to the NewEco project funded by the EIT Raw Materials, ERAMET Research has improved and tested at pilot scale the hydrometallurgical process of ERAMET Sandouville plant to strengthen its position in the high-purity nickel market. This project is one of the first success story of the EIT Raw Materials.

Rare earth recovery from secondary resources

n the ENVIREE project a complete extraction process for secondary sources of REE is investigated. Read more

New process saves energy

Outotec has developed a process for hot magnetic separation of metallic fine-grained concentrates and products. The process has been verified with the aid of Swerea MEFOS’s pilot plant. Read more

Development of high-purity solar silicon

In Swerea MEFOS news, May 2016 you can read about Swerea MEFOS and Elkems collaboration to identify the most efficient method/process for producing solar Silicon.

A simple and innovative way to treat industrial effluents from the production of alumina

Read about Extracthive’s successful project for the aluminum oxide producer Alteo.

Implementation of a new industrial plant based on pilot scale developments that ables to produce nickel salts and metals

Thanks to the NewEco project funded by the EIT Raw Materials, ERAMET Research has improved and tested at pilot scale the hydrometallurgical process of ERAMET Sandouville plant to strengthen its position in the high-purity nickel market. This project is one of the first success story of the EIT Raw Materials.

Read more in the EIT Raw Materials CLC Central Newsletter, July-August 2017

New mould thermal monitoring system for a steel slab caster

The Materials Processing Institute (MPI) was asked to design and install a new mould thermal monitoring system for its client’s continuous slab casting machine. Read more

New technique curbing vanadium import

Vanadium is an economically important metal in the EU. To produce vanadium in Europe, raw materials must be imported, despite the existence of several unused vanadium resources in the EU. Swerea MEFOS and Mustavaaran Kaivos Oy works together in a project where the aim is to develop methods to extract vanadium. Read more