27 Mar Łukasiewicz-IMN operates a unique rotary kiln to pilot the Waelz process in semi-industrial conditions

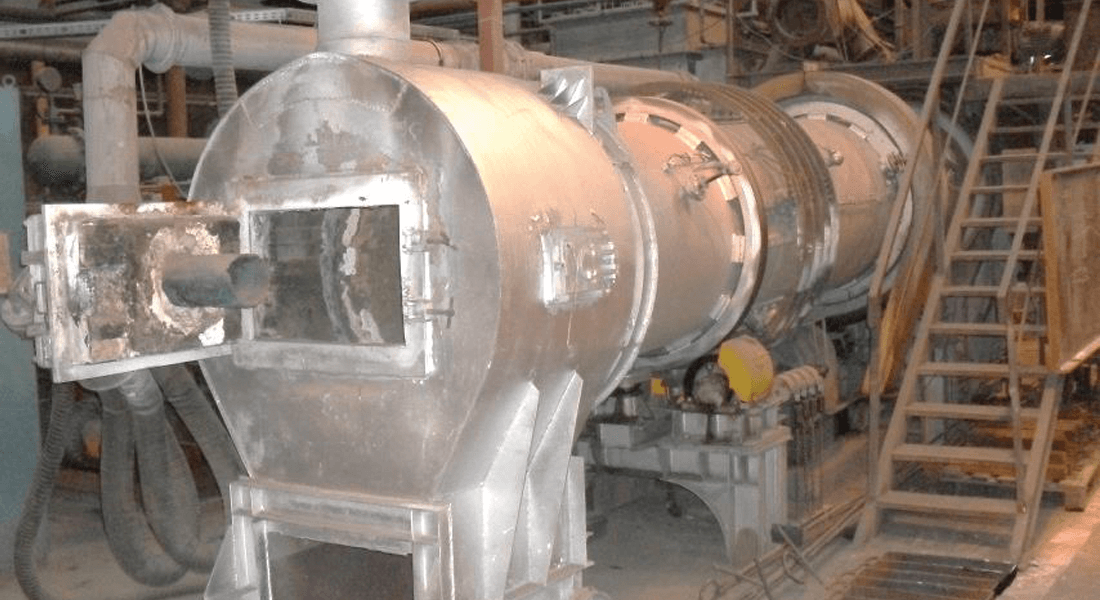

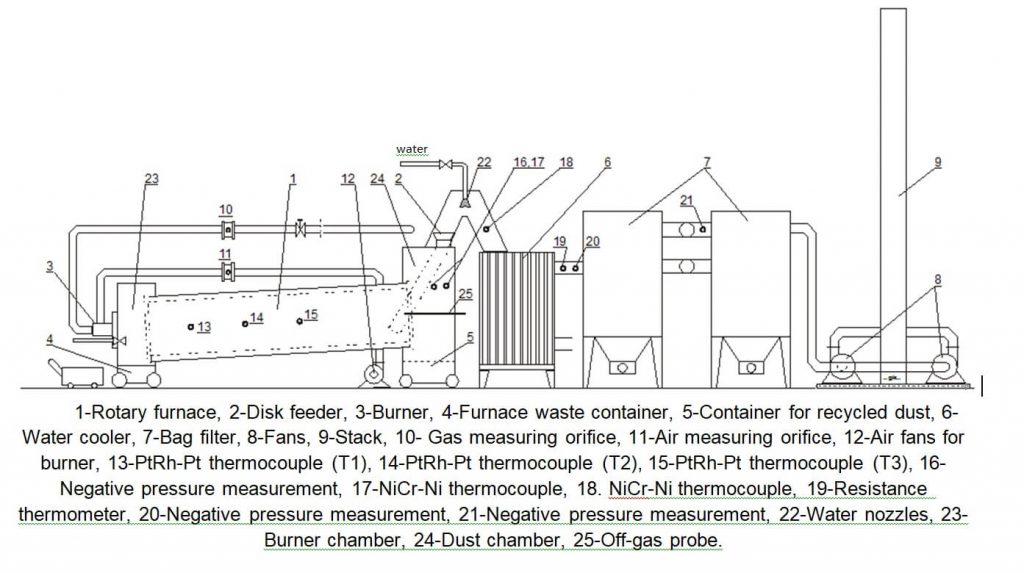

Łukasiewicz-IMN‘s installation is a pilot rotary kiln consisting of a kiln itself (6 m long and 0.8 m internal diameter) together with a cooler and bag filters. The installation is used for piloting the Waelz process in semi-industrial conditions.

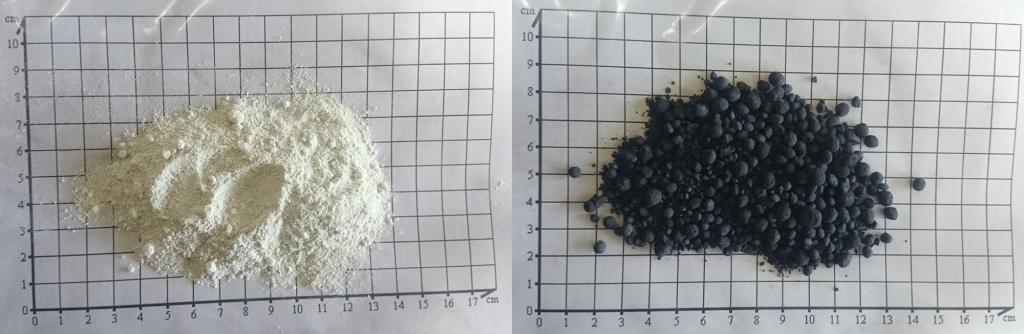

Recently the installation was successfully applied in studies of treatment of zinc and lead containing materials coming from industrial waste and/or intermediates (for example: dusts from steel industry, post-process slag and materials from landfills (heaps) at former metallurgical plants). The studies were commissioned by some European companies interested in potential recycling activities. Materials used in the process contained from 5 to 35% Zn and from 2 to 15% Pb, which means materials of much lower metal value than typical EAF dusts were tested in the studies. As a result of the process, zinc and lead oxide concentrate (Zn + Pb content up to 75%) and slag in a form of iron concentrate (40-55% Fe) were produced. The performed tests resulted in development of a technology (process parameters) for treatment of specific Zn and Pb containing waste materials of various origins.

The studies were carried out in a counter-current system (i.e. process gases moved in the opposite direction to the material), however it is possible to change the direction of process gas flow and operate in a co-current system. The furnace is equipped with three thermocouples to measure the temperature inside the furnace, which provides possibility for more accurate process control. In addition, it is possible to measure the composition of process gases directly at the furnace exit, which makes sampling of the gases without air pollutants possible. The residence time of the material in the furnace can be regulated by varying the furnace rotation speed from 0.05 to 0.55 revolutions per minute.

This project has been carried out within the Metnet network. This network consists of several pilot plants in Europe, covering many different aspects of mineral processing, metallurgy and production of metals. Through Metnet the customers have access to a network of knowledge that can work cross-sectorial and innovatively by combining the expertise of all members. You can find more about the METNET network here.